Vapor Recovery

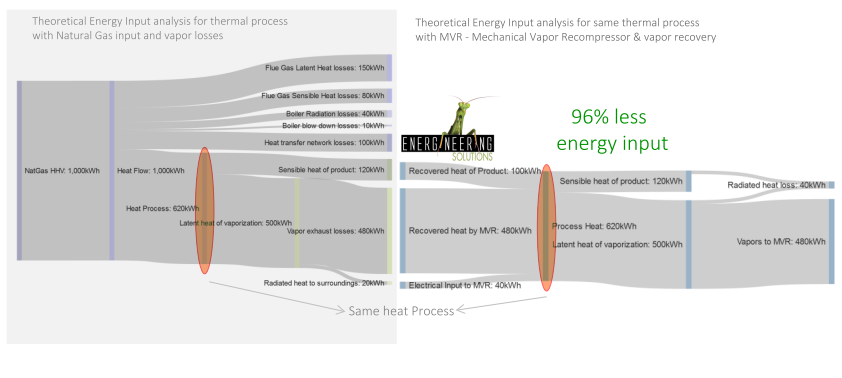

Vapors exhausted from heat processes are largely neglected. Still they are a huge cause of profit loss, since this "waste heat" form is compensated with primary energy input (usually fuel combustion).

From our point of view process redesign is not only possible but very profitable for all such cases, even the most challenging ones. Taking advantage of the latent heat of vapors which is huge (600-1000 kWhs / ton of evaporated water, depending on efficiency of boilers) is possible with the implementation of MVR technology that consumes roughly 10% this energy (40-80 kWhs el / ton evaporated water) for the compressor motor.

Drying, evaporation, condensing of liquids, even frying, boiling and broiling are processes that can be greatly improved in terms of energy consumption and produce even better product quality once addressed optimally with MVR.

Energineering solutions is collaborating with accredited MVR manufacturers and based on our long experience with industrial projects we can guarantee successful implementation and fruitful results from the first day.